Reported by Jasper Beckers. Powered by FuseNet

With help from FuseNet I was able to spend half a year at the DIII-D National Fusion Facility in San Diego, California. The site is operated by the company General Atomics, partnering with the US Department of Energy. FuseNet support was vital, especially due to the so-called Californian sun tax!

At DIII-D my goal was to build a table-top version of their Neutral Beam Ion Sources. These sources have been in operation for decades and due to their complexity little effort has been spent to improve them. However, improving them has the potential to increase the operational capability of DIII-D: better injected power and perveance, and better reliability when operating with Helium. This was the motivation for a table-top experiment.

Making an NBI source system from scratch: Building, modeling and coding

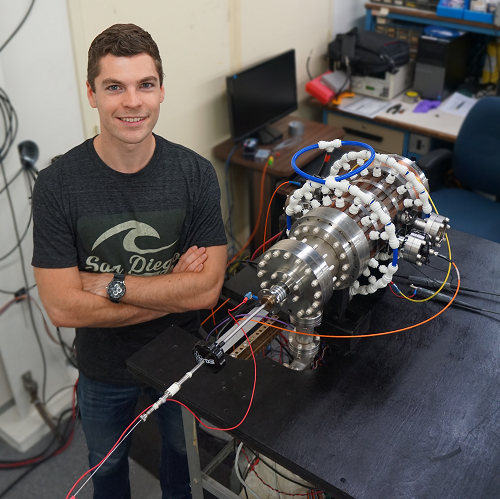

When I arrived, this new experimental setup was just a vague idea. Therefore first few weeks were spent figuring out the requirements and the design, and inventorizing the available hardware. It turned out there was a large surplus of material including power supplies, vacuum systems, and gas lines. Some new parts had to be ordered or manufactured on-site, but thanks to the great assistance from everyone in the Beam group this procedure did not take too long. All in all, I could start assembly quickly, and first plasma in the new ion source was obtained after no more than two months.

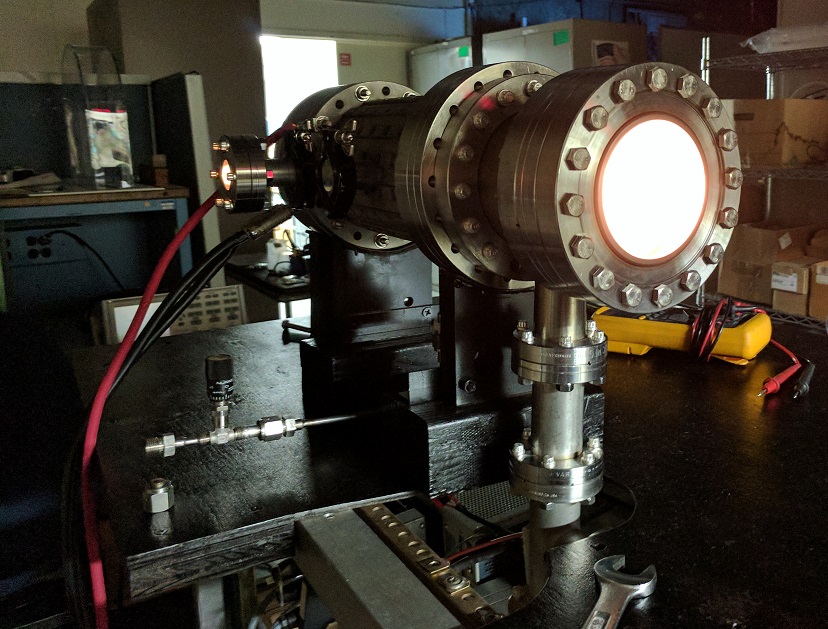

In parallel with the assembly process I performed modelling work in COMSOL in order to validate the design, and to ensure the magnetic confinement of energetic electrons would be as expected. After first plasma the next objective was to learn about what exactly was happening inside the chamber. The focus shifted to the diagnostics, which also had to be designed from the ground up. Multiple spectrometers were attached on window ports, and a translatable Langmuir probe was built from scratch. A watercooling system was also designed and built to allow for steady-state operation, and prevent the delicate confinement magnets from losing strength.

The final step in the build process was software-based: writing code to remotely control the device and operate it. On top of this a GUI was built. After a little more than four months the device was officially taken into use, and data collection started. I mostly experimented with different pressures, voltages, filament powers, and insulation materials. The next step is to analyze the data and make

recommendations for improvement of DIII-D’s ion sources. These improvements will most likely be tested at the EAST facility in China in 2018.

What I enjoyed most in San Diego was experiencing all steps of a project: from initial brain-storming and design to assembly and operation. That, and the Southern Californian sun of course! I’d like to thank FuseNet once again, and also my local supervisors Brendan Crowley and Tim Scoville for their guidance during my work at DIII-D!